Bakery packaging machine is a horizontal wrapping machine, configured with 3 axis servo driven technics, high speed, low noise, used for packaging all kinds of bakery food.

How does cake packing machine work?

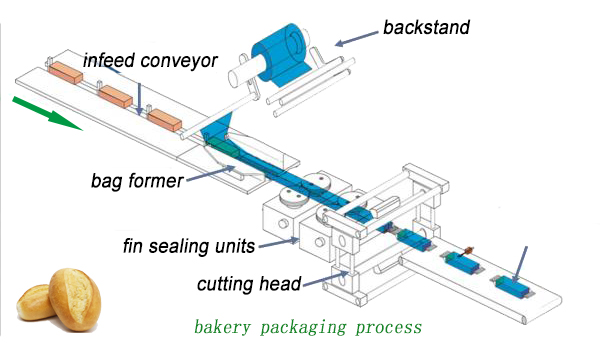

This bakery packaging machine has an infeed conveyor, a film roller, a fin seal unit and an end seal unit. The cake packing process is the infeed conveyor push cake into film tube which is formed bag former, then sealed by fin seal unit and end seal unit.

Features of Bakery Packaging Machine:

- Three servo control with touch screen operation.

- Carbon steel body, all parts touched with food are SUS304 material.

- High precision sealing parts, fast packing speed.

- Expand with automatic feeding conveyor for full automation.

- Date printer, labeling device can be chose.

Customized Solution for Fully Automatic Bakery Packaging System:

We make customized packing system according to bakery features, such as bakery manufacturing capacity, size, shape, etc. For different packing requirement, we can use different sorting and convey machine.

Contact us by email: info@cankeytech.com, if you have bakery packing requests.

Horizontal Cake Packing Machine Price:

Choose different configurations according to different packaging requirements, and the cake packing machine price is around USD 6000 – 20000/set.

Bakery Packaging Video:

Cake Packing Machine Specifications:

| Model | CK-ZS450 |

| Film width | Max 450mm |

| Bag width | 50-180mm |

| Product height | Max 80mm |

| Film diameter | 320mm |

| packing speed | 40-230bags/min |

| Machine size | 4020*820*1450mm |

| Weight | 1050kg |

Payment&Shipment&Warranty Term:

- Payment: T/T is preferred, 40% of cargoes value to be paid after signed the contract, the balance to be paid before shipment. L/C is acceptable.

- Leading time: 15-30 days, from machine’s quantity and configurations.

- Warranty period: 1 year from the date of shipment, whole life maintenance supports.

How to Maintenance And Clean The Bakery Packing Machine?

(1) Turn off the power before cleaning.

(2) Clean the machine each time after packaging.

(3) Never spray the water directly on the machine when cleaning.

(4) Main components to be cleaned:

Remove the product chips stored up in the conveyance line of the cake.

Brush off the film chips adhered to the sealing surface of the sealer by the wire brush applied with the silicone oil.

Clear the dirt on the control board, safety cover and painted surface by a soft cloth. Do not use hard cloth, it will be scratches on the surface of the controller.

Reviews

There are no reviews yet.