This chamber shrink wrapping machine is suitable for bowl noodles, cup instant noodles, bath bomb, soap and other materials. The shrink wrapping machine for bath bomb is designed for assembly line operations, high volume shrink wrapping. According to the specific conditions of product packaging, an automatic feeding system can be selected to realize unmanned operation of feeding materials, continuous operation, and overall higher efficiency. After packaging, the sealing is linear, and the lines are clear and beautiful.

Working Principle of Shrink Wrapping Machine for Bath Bomb:

The bath bomb that have been packed with film are sent to the automatic shrinking furnace through the output conveyor, and run in the shrinking furnace through the mesh belt, and the thermal energy efficiency during the operation can achieve the purpose of shrinking. The products that have been packaged with film are sent to the automatic shrinking furnace through the output conveyor, and run in the shrinking furnace through the mesh belt, and the thermal energy efficiency during the operation can achieve the purpose of shrinking.

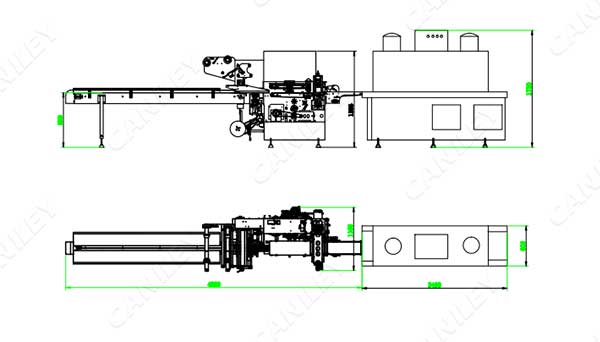

Chamber Shrink Wrapping Machine Constitute:

Control panel, sealing and cutting part, photoelectric detection part, punching device, waste collecting device, heat shrinking part

Optional device:

Date printer, automatic bottle unscrambler, automatic feeder, automatic grouping device

Features of Shrink Wrapping Machine for Bath Bomb:

- Adopt programmable logic controller (PLC) control, reduce mechanical contacts, low system failure rate, more stable and reliable operation.

- Frequency conversion speed regulation, to change the packaging speed, only need to rotate the potentiometer knob connected to the frequency converter.

- The main box is welded with 12mm thick steel plate, and the internal stress is eliminated by post-weld heat treatment. No shaking at high speed, no deformation of the box.

- This machine adopts a toothed chain continuously variable transmission, and the length of the packaging bag can be changed by rotating the handle.

- Bidirectional photoelectric tracking system can ensure that the film is cut at the required position and the cut point is accurate.

- The leakage protection switch installed in this machine can ensure the safety of people and machines.

Packaging Materials:

Shrink film such as PVC and OPP

Reviews

There are no reviews yet.