Food Packaging Machine Manufacturers

Food packaging is an essential process that helps protect and preserve food products before they are consumed by customers. With the growing demand for food packaging solutions, the market is flooded with a wide range of food packing machine manufacturers. Our company is one of them.

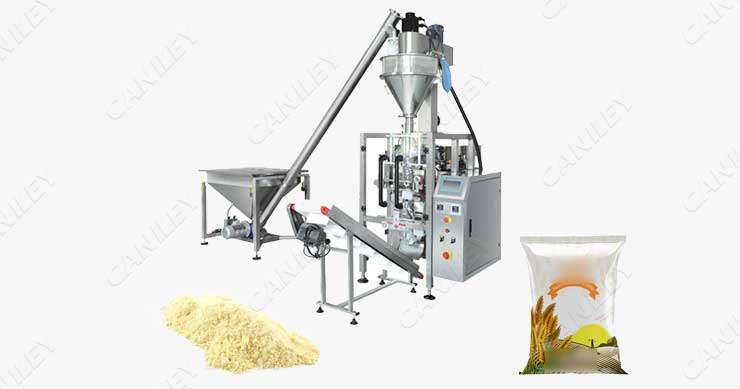

Firstly, we pride ourselves on the quality of our machines. Our food packing machines are designed and built using high-quality materials, ensuring their durability and reliability. We understand that the packaging process is critical to the success of any food product, and as such, we ensure that our machines are of the highest standard, capable of delivering efficient, effective, and consistent results.

Secondly, we offer a range of food packing machines that cater to different food packaging needs. We have machines that can handle both solid, liquid and powder products, ensuring that our clients have a wide range of options to choose from. Our machines are also customizable, allowing our clients to specify the exact specifications...