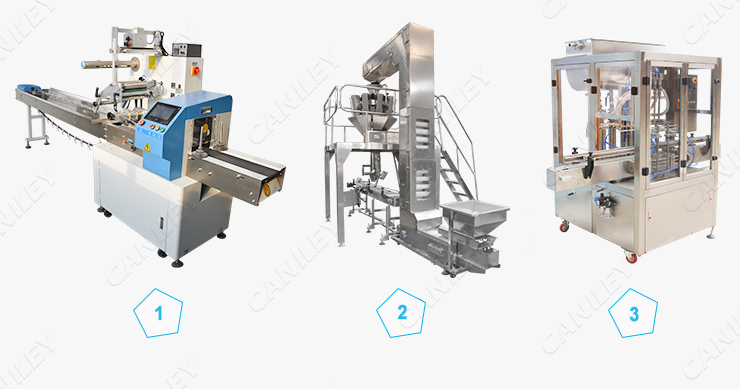

Types of Coffee Packaging Machine

Coffee is one of the most popular beverages in the world. It is consumed by millions of people every day, and as a result, there is a huge demand for coffee packaging machines. These machines are designed to pack coffee into various packaging types, such as drip bags, stick packs, and sachets. In this article, we will discuss the three types of coffee packaging machines.

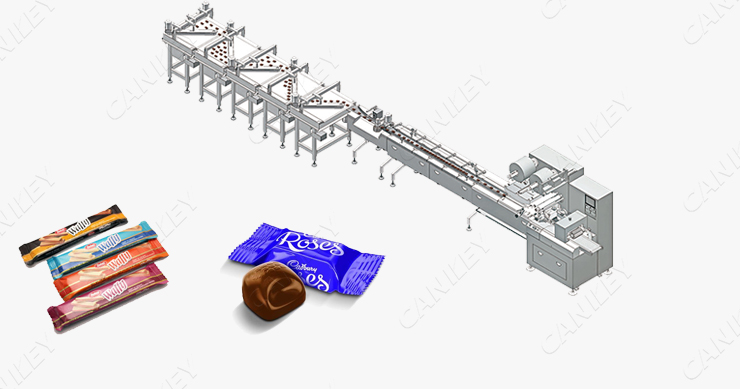

Drip bag coffee packing machine

Drip bag coffee packing machines are designed to pack coffee into individual drip bags. These bags are made of filter paper and are designed to be used with a coffee cup. The machine first forms the filter paper into a bag shape, and then it fills the bag with the desired amount of coffee. The machine then seals the bag to ensure that the coffee stays fresh.

The drip bag coffee packing machine is perfect for those who want to make a single cup of coffee quickly and easily. It is also a...