Automatic Tomato Sauce Packaging Machine Using

In the fast-paced world of food processing, efficiency and precision are paramount. One significant advancement in this field is the introduction of automatic packaging machines, which have transformed the way various products, including tomato sauce, are packaged. This article explores the using of automatic tomato sauce packaging machines.

Automatic tomato sauce packaging machine using:

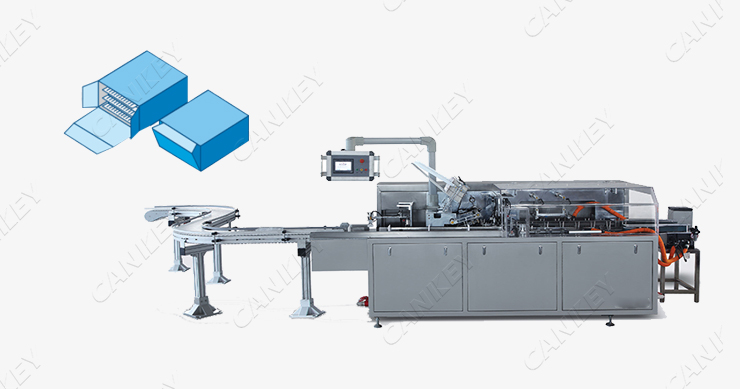

Automatic tomato sauce packaging machines are sophisticated devices designed to streamline the packaging process, from filling to sealing and labeling. These machines utilize cutting-edge technology to ensure accuracy, speed, and hygiene in the packaging of tomato sauce and other liquid products.

Key features:

Precision and consistency: Automatic packaging machines ensure precise measurement and filling of tomato sauce, eliminating variations in product quantity. Consistent packaging enhances product quality and customer satisfaction.

Efficiency and speed: These machines significantly increase production efficiency by automating the packaging process, reducing the need for manual labor. High-speed capabilities contribute to faster production cycles, meeting the demands of a dynamic market.

Hygiene and sanitation: Automatic machines are designed with...