Dry Fruit Packing Machine Manufacturers

In today's fast-paced world, the demand for convenience and efficiency has revolutionized various industries, including food processing. One such sector that has witnessed significant advancements is the dry fruit packaging industry. With the rise in consumer preference for healthy snacks and the need for longer shelf life, dry fruit packing machines have become crucial for businesses. And there are many dry fruit packing machine manufacturer, design solution for dry fruit packaging.

The importance of dry fruit packing machines:

Dry fruit packing machines play a vital role in the packaging process, ensuring the preservation and protection of dry fruits from external elements that can compromise their quality. These machines automate the packaging process, enhancing efficiency, minimizing errors, and reducing manual labor costs. With precise weighing, sealing, and labeling capabilities, these machines enable companies to maintain consistency, improve productivity, and meet the demands of a rapidly growing market.

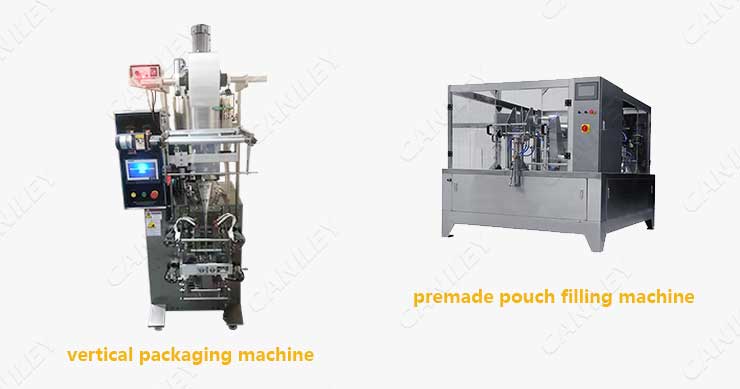

Technologies employed by dry fruit packing machine manufacturers:

Automated weighing systems: Dry fruit packing machines employ advanced weighing...