This soap wrapping machine model can be customized by users’ working requirement to fit varied industries of Pharmacy, Cosmetics, Foods, Stationery & Electronics, etc.

Features of Automatic Soap Wrapping Machine:

- Feeding by conveyor: soap is fed by conveyor to save working seconds & enhance efficiency. The low friction conveyor is a good options to prevent the soap from scratching.

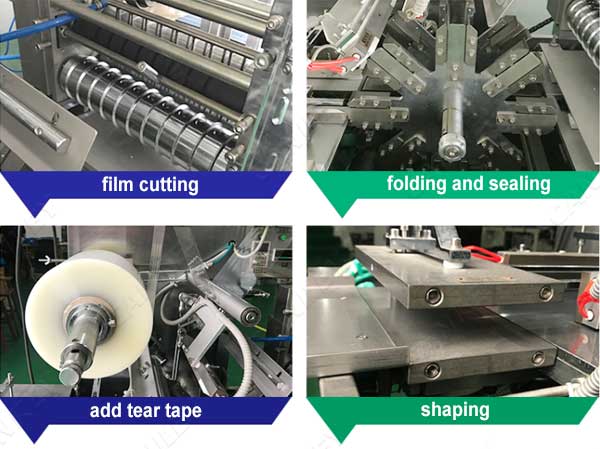

- Clawing type film deliverer: the dual clawing type film deliverer to ensure the stable film feeding and prevent working problem from static.

- One way film feeding unit: this unit is designed by one way bearing to ensure film without rewinding.

- Add tear tape: it can lift the string tab to help user tear the packaging film easily.

- Simple operation: worker needs to press only one button to control the packaging speed without complicated adjustment.

This soap wrapping machine can provide the versatile solution you are looking for, as follows:

- Protection – prevent the soap from going bad at too high temperature.

- Security – safe operation, no mechanical damage.

- Seal area flexibility – allows the longitudinal seal to be positioned either on trailing edge or on the base of the soap, depending on soap design and marketing needs.

- Geometrically exact end folds – giving that sleek finished look.

- Easy open tear tape facility.

The wrapping mchine works stable, basing on production capacities, user can adopt the manual, semi-auto or fully automatic machine to create the better efficient productio.

Soap Wrapping Machine Specification:

| Model | CK-BTB-300A |

| Packing Material | bopp film and tear tape (bopp thickness: 22μm,tear tape:2.5mm,3mm) |

| Packing Speed | 40-80boxes/min |

| Max Packing Size | L 240*W 120*H 60 mm |

| Voltage and Power | 220V 50Hz 5kw |

| Machine Weight | 500kg |

| Machine Size | L 2000*W 700*H 1400 mm |

Reviews

There are no reviews yet.