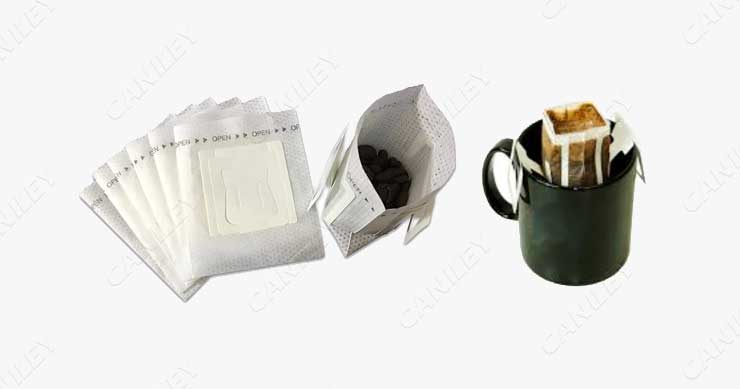

What is drip coffee filter bags packaging? Drip coffee filter bags is a very popular packaging method at present. It was born in Japan in the 1990s and has now developed into one of the standard packaging methods for single-serve coffee. And its popularity is gradually expanding around the world.

Drip coffee filter bags packaging mainly contains:

- Coffee powder

- Inner bag (filter paper packaging)

- Hanging ears (cardboard)

- Deoxidizer (mainly nitrogen, isolating air to prevent coffee oxidation)

- Outer bag (protected from light)

Each bag is small and flat before being filled with coffee for easy storage. To brew a cup of coffee, consumers simply open the bag, remove the filter bag, tear off the top, and shake to flatten the coffee inside. Then put the hanging ears on the cup and pour the hot water slowly. Then take out the drip coffee bag and throw it away.

The packaging process of drip coffee filter bags packaging:

- Trial operation by jogging the drip coffee packaging machine. Turn the feed clutch handle to the disconnect mark. After confirming that there is no abnormality, start the machine idling.

- Adjust the stepless speed governor to the slowest position according to the mark.

- After the machine is stopped, send the packaging film along the former to the longitudinal sealing mold according to the steps of the film threading diagram, press and seal, disengage the paper-pulling clutch with the right hand, pull the film to the paper-pulling wheel with the left hand, and close the paper-pulling clutch.

- Start the packaging mechanism to empty the bag and check its sealing quality.

- Close the unloading handle and observe whether the unloading time is correct.

- Pour a small amount of coffee into the hopper, start the packaging machine, test the finished product, and check whether the packaging weight meets the requirements.

- After the above preparations are completed, start the machine and start mass production.

More and more advanced technology makes the packaging speed of drip coffee filter bag packaging faster and better, and the packaging effect is better, which can meet a large number of market demands.